Cheesmaker for a day....

By Elaine Giammetta

Cheese and I have been having a love affair for years. I’m not sure where the passion stems from but trust me, it can be all consuming at times. Whether it has a pungent blooming rind, is a mellower cloth bound variety, is spreadable or comes in a wheel, I just love it. Any time that Louis and I visit a farmers’ market or specialty store, I always seem to make a beeline straight to the cheese sellers.

Cheese and I have been having a love affair for years. I’m not sure where the passion stems from but trust me, it can be all consuming at times. Whether it has a pungent blooming rind, is a mellower cloth bound variety, is spreadable or comes in a wheel, I just love it. Any time that Louis and I visit a farmers’ market or specialty store, I always seem to make a beeline straight to the cheese sellers.

Over the past few months, Louis has been talking about the cheeses of America, and while on location in Vermont, Shelburne Farms offered me the opportunity to be a cheese  maker for a day. I was excited; I was actually going to live out one of my cheese dreams, to work with a cheese artist.

maker for a day. I was excited; I was actually going to live out one of my cheese dreams, to work with a cheese artist.

I'd watched documentaries and read about artisinal cheese makers, however, this was my first foray into actually making my beloved dairy product. It was a brisk autumn morning in October as I set out at 4:30 a.m. to meet up with Nat Bacon, the "Head Cheese" if you will, at their location in beautiful Shelburne. Before I get into the actual class, I must take a moment to talk about the setting. Traveling through northern Vermont at peak foliage season was an added bonus. Part of the farm’s property is adjacent to Lake Champlain and the vistas of the Green Mountains are both breathtaking and peaceful. As I entered the property through the stone gates, I was greeted by an image, of what appeared to me to be an English Estate, but in reality was the Farm Barn. Beautiful cupolas, turrets and stone nestled  into a corner of 400 pristine acres. One could easily think they are somewhere in the English countryside, add to that image leaves of yellow, gold, orange and red and, well, you get the idea.

into a corner of 400 pristine acres. One could easily think they are somewhere in the English countryside, add to that image leaves of yellow, gold, orange and red and, well, you get the idea.

My small group, about 10, met at the barn at 7:30 a.m. and started off with a brief video, Sun to Cheese, introduction to the farm and its operation. Images of big brown eyed cows, lush green fields, and staff happily going about their daily chores filled the screen. It was a nice way to become acquainted with everything that the Farm is about. After the screening we were treated to freshly baked (on site) breads and Honey Crisp apples from a neighboring orchard. A Vermont breakfast for sure, local produce that tasted like a new day, fresh and crisp. The Farm works closely with area businesses, the orchard and bakery, to fulfill their mission and support the local economy, a win-win situation.

Our cheese team consisted of Nat, Paul (pictured right) and Andy, who are all certified cheese makers. As I gazed through a wall of windows at what would be my classroom, Paul was working away in my soon to be sterile environment for the next 8 hours, Nat provided a brief orientation which included hygiene expectations and the day's itinerary. The Farm typically does not allow visitor’s into the actual cheese making room, how cool is this! First a tidbit about the cows: "Great milk equals great cheese," and Brown Swiss cows are well known for theirs. The Farm has the largest herd of Brown Swiss cows, (100) and have been Certified Humane, meeting the standards of humane farm animal care. A wide variety of grasses and other native plants found in the pastures are important

Our cheese team consisted of Nat, Paul (pictured right) and Andy, who are all certified cheese makers. As I gazed through a wall of windows at what would be my classroom, Paul was working away in my soon to be sterile environment for the next 8 hours, Nat provided a brief orientation which included hygiene expectations and the day's itinerary. The Farm typically does not allow visitor’s into the actual cheese making room, how cool is this! First a tidbit about the cows: "Great milk equals great cheese," and Brown Swiss cows are well known for theirs. The Farm has the largest herd of Brown Swiss cows, (100) and have been Certified Humane, meeting the standards of humane farm animal care. A wide variety of grasses and other native plants found in the pastures are important  contributors to the quality of the milk. And yes, how happy the cows are is important. Nat explained to us that the farmers can determine if the cows are happy and content by how they lumber along as they walk back from their grazing. Sort of reminds me of how I determine if my Thanksgiving dinner guests look after the meal, lumbering over to the couch to watch football.

contributors to the quality of the milk. And yes, how happy the cows are is important. Nat explained to us that the farmers can determine if the cows are happy and content by how they lumber along as they walk back from their grazing. Sort of reminds me of how I determine if my Thanksgiving dinner guests look after the meal, lumbering over to the couch to watch football.

As we trundled behind the scenes, through the shipping dept, really just 4 desks, we were treated to a peak into one of the cheese storage areas. When I asked Nat what the value of the inventory was in this one location, he told us about $1 million. Staggering when you realize that this is just one of their storage sites. I'd like  to point out that Shelburne Farms is a farmstead operation. You won't find mass production here; this is all about hands-on craftsmanship, one batch at a time. Nat corrected me when I called him an artisan, he said he prefers the term craftsman.

to point out that Shelburne Farms is a farmstead operation. You won't find mass production here; this is all about hands-on craftsmanship, one batch at a time. Nat corrected me when I called him an artisan, he said he prefers the term craftsman.

This member supported, non-profit, educational facility, is a spectacular example of how a farm and its community can work together for the greater good of the environment. Their mission: "to cultivate a conservation ethic in students, educators and families who come here to learn," and they have it down pat.

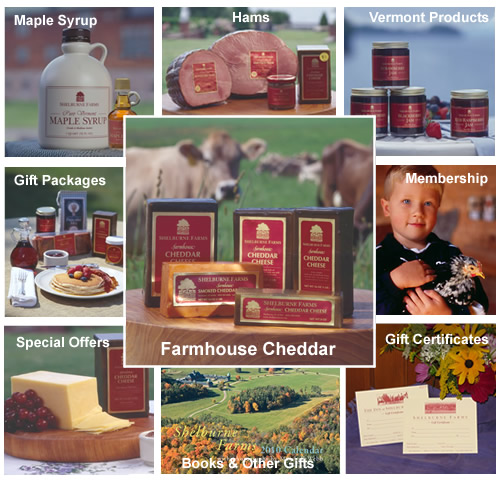

I need to point out that unlike many larger cheese makers, Shelburne’s Farmstead Cheese Making focuses on one type of cheese with an emphasis on maximum quality, not quantity. That being said, it is also important to note that 70% of the milk produced on the farm, stays on the farm. At the time I was there, they were making cheese 7 days a week. After all, one can’t tell the cows, "Hey no milk production today girls." However, we did learn several interesting facts: when cows are barn fed (winter) the butter fat and protein levels increase and that cold weather does impact milk production. Besides icy dirt roads, which make milk transport difficult, keeping the wash water at the right temperature is difficult even in the best circumstances, but I digress.

I’ve toured other cheese making facilities in the past and most of them are a good place to ‘get your feet wet,’ when learning about this energy sapping art, but I’m ahead of myself. The first thing we all had to do was don hair nets, booties and cheese maker shirts, then we scrubbed! It felt like I was prepping for surgery, but you can’t take short cuts on cleanliness. The ‘bath’ and I became very good friends as every time I took a photo or tweeted, I had to go through the whole sterilization process again. To say that my hands were raw at the end of the day is an understatement. Ahh, the joys of the hands-on experiences.

I’ve toured other cheese making facilities in the past and most of them are a good place to ‘get your feet wet,’ when learning about this energy sapping art, but I’m ahead of myself. The first thing we all had to do was don hair nets, booties and cheese maker shirts, then we scrubbed! It felt like I was prepping for surgery, but you can’t take short cuts on cleanliness. The ‘bath’ and I became very good friends as every time I took a photo or tweeted, I had to go through the whole sterilization process again. To say that my hands were raw at the end of the day is an understatement. Ahh, the joys of the hands-on experiences.

Of course we couldn’t start until the main ingredient was delivered and even this system is unique. The milk truck delivers every day at the same time and puts a note on the window advising the weight of the milk that is being pumped in. No face to face contact except through a window! The milk is then fed into a large open top tank, think huge bathtub with stand mixer attachments. The walls are hollow to allow heated water (wash water) that’s been pumped in to surround, or bathe, the milk without mixing with it, see I told you bath tub. Of course the water has to be a certain temperature (and it gets HOT) in turn heating the milk. You can just imagine the responses I got to my tweets about taking the milk’s temperature. When the temperature was just right the rennet  was added and Paul continued taking temperature readings.

was added and Paul continued taking temperature readings.

It takes about 30 minutes for the rennet to do its job and coagulate the cheese. There are two ways one can test to determine if the ‘cheese’ is ready to be cut; the common practice is the knife blade test dipping the tip of a knife into the ‘cheese’ and seeing if it leaves and impression. For me, I liked the handprint test; after all I’m more of the hands on, or in this case, hands-in, type. Think about that mattress advertisement with memory  foam, where the person presses their hand and an imprint is left, same thing except you are pressing into cheese.

foam, where the person presses their hand and an imprint is left, same thing except you are pressing into cheese.

Once ready the cutting begins using a rake type of tool, to separate the curds and whey (I wanted to recite Little Miss Muffett so bad). We witnessed the cadre of tests necessary at  various stages to test acidity levels and how much salt to add, reinforcing how art and science work together with tasty results.

various stages to test acidity levels and how much salt to add, reinforcing how art and science work together with tasty results.

I think that the hardest part has to be the flipping. Flipping is an integral step designed to remove as much moisture as possible, and let me tell you my cheese loving friends, it is HARD work.  The cheese, now in slab form, needed to cool evenly, and there is even a formula to determine how high the slabs will be layered. The cheese makers not only adjusted the speed of the paddles, they also changed the slab height from 4 to 3. Hey don’t laugh, in this form, with added water weight, this stuff is heavy and the constant bending over the side of the vat is murder on the back.

The cheese, now in slab form, needed to cool evenly, and there is even a formula to determine how high the slabs will be layered. The cheese makers not only adjusted the speed of the paddles, they also changed the slab height from 4 to 3. Hey don’t laugh, in this form, with added water weight, this stuff is heavy and the constant bending over the side of the vat is murder on the back.

Once the cheese maker decides that the bulk of the moisture has been removed, the slabs are ‘cut’ up once again but this time using a machine that attaches to the side of the tub. This is a very quick process and we left the masters to handle it because once on a roll you’ve got to be ready. After re-cut the cheese curds are scooped into a bucket and then poured into ‘hoops’ that are lined with polymer based weaved cloth.

Once the cheese maker decides that the bulk of the moisture has been removed, the slabs are ‘cut’ up once again but this time using a machine that attaches to the side of the tub. This is a very quick process and we left the masters to handle it because once on a roll you’ve got to be ready. After re-cut the cheese curds are scooped into a bucket and then poured into ‘hoops’ that are lined with polymer based weaved cloth.  The next day when the cheese would get its plug test, the cloth would be discarded, and the cheese would be put into the refrigerated vault for aging. We wouldn’t be there for the plug test, which determines how long they would age our batch, but were assured they’d let us now, which they did. Our batch is sentenced to 2 years in the cooler! I’ve marked my calendar because you can be sure that I will be buying some of the cheese that I worked hard to help make.

The next day when the cheese would get its plug test, the cloth would be discarded, and the cheese would be put into the refrigerated vault for aging. We wouldn’t be there for the plug test, which determines how long they would age our batch, but were assured they’d let us now, which they did. Our batch is sentenced to 2 years in the cooler! I’ve marked my calendar because you can be sure that I will be buying some of the cheese that I worked hard to help make.

Shelburne Farms’ cheeses are available online or if you live in New England at select locations. I highly recommend taking advantage of their Cheese Maker for a Day Class and further details can be found on their website. I had a fantastic time and have come away with a greater respect for those who make one of my favorite foods. For those of you who may guffaw at paying a higher price for artisan cheeses, trust me when I say, they’ve earned it. My classmates were awesome and I want to thank them for their patience as I took numerous photographs, particularly those who jumped in to take some of me. That Vermont Spirit, you can’t beat it.

Shelburne Farms’ cheeses are available online or if you live in New England at select locations. I highly recommend taking advantage of their Cheese Maker for a Day Class and further details can be found on their website. I had a fantastic time and have come away with a greater respect for those who make one of my favorite foods. For those of you who may guffaw at paying a higher price for artisan cheeses, trust me when I say, they’ve earned it. My classmates were awesome and I want to thank them for their patience as I took numerous photographs, particularly those who jumped in to take some of me. That Vermont Spirit, you can’t beat it.

Nat said it best, "You have to be humble to make cheese." He wasn’t kidding!

View the cheesemaking slideshow

For more about Shelburne Fams visit thier website : www.shelburnefarms.org

For more on the cheeses of Vermont visit: The Cheeses of Vermont